Description

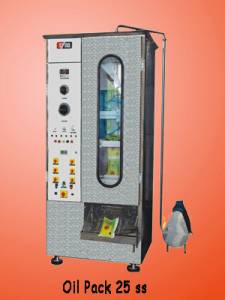

Fully Automatic Pouch Packing Machinery: Revolutionize Your Packaging Process

Elevate your production efficiency and product presentation with our cutting-edge, fully automatic pouch packing machinery. This robust and versatile machine seamlessly integrates multiple processes, from feeding and forming to filling, sealing, and outputting finished pouches, all with unparalleled speed and precision. Designed for high-volume production environments, this machine significantly reduces labor costs and minimizes manual handling, ensuring consistent quality and maximizing your return on investment.

Key Features & Benefits:

- Complete Automation: From raw material input to finished product output, this machine handles the entire packaging process automatically, significantly reducing reliance on manual labor. This minimizes errors, increases consistency, and boosts overall productivity.

- High-Speed Operation: Engineered for speed and efficiency, our machinery achieves exceptional throughput, processing a large volume of pouches per hour. Specific speed depends on pouch size, product type, and selected configuration. Contact us for customized speed specifications.

- Versatile Pouch Types: Compatible with a wide range of pouch types, including pillow pouches, stand-up pouches, three-side seal pouches, and more. Easily adaptable to different film materials, allowing flexibility in packaging design and product offerings. (Specify supported pouch sizes and materials here, e.g., "Supports pouches ranging from 50mm x 80mm to 300mm x 450mm, compatible with various film materials including PET/PE, BOPP/PE, and more.")

- Precise Filling System: Equipped with a sophisticated filling system ensuring accurate and consistent product weight in each pouch. Multiple filling mechanisms are available depending on the product type, including volumetric filling, weight filling, and liquid filling systems. (Specify available filling systems here).

- Robust Construction: Built with high-quality stainless steel and other durable materials, ensuring long-term reliability and minimal maintenance. The machine is designed for continuous operation in demanding industrial settings.

- User-Friendly Interface: Intuitive touch screen control panel provides easy operation, monitoring, and troubleshooting. Real-time data display ensures optimal process control and allows for quick adjustments as needed.

- Advanced Safety Features: Incorporates numerous safety features, including emergency stop buttons, safety guards, and interlocks, ensuring a safe operating environment for personnel.

- Customizable Options: Offers a wide range of customization options to cater to specific product and packaging requirements. Options include various filling systems, sealing mechanisms, gas flushing capabilities, and more. (List example customizations here, e.g., "Nitrogen flushing for extended shelf life", "Date/time coding options", "Different sealing styles").

Technical Specifications:

(Insert detailed technical specifications table here, including dimensions, power requirements, production capacity (pouches per hour), air pressure requirements, etc.)

Applications:

Our fully automatic pouch packing machinery is ideal for a diverse range of industries and products, including:

- Food and beverage

- Pharmaceuticals

- Cosmetics

- Chemicals

- Agricultural products

Contact us today to discuss your specific packaging needs and request a customized quote! We'll help you select the perfect machine to optimize your production and achieve your business goals. Our team of experts will provide comprehensive support throughout the entire process, from installation and training to ongoing maintenance and service.