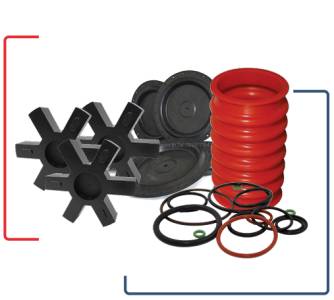

Our custom rubber molded parts offer a superior solution for a wide range of applications, providing unmatched performance, durability, and design flexibility. Manufactured using state-of-the-art molding techniques, these parts are engineered to meet the most demanding specifications and exceed industry standards.

Key Features & Benefits:

Applications:

Our rubber molded parts find applications in numerous industries, including:

Materials:

We work with a wide range of rubber compounds to meet diverse application requirements. Please consult with our engineers to determine the best material for your specific needs.

Request a Quote:

Contact us today to discuss your project requirements and receive a customized quote. Our experienced team will work with you to develop the perfect rubber molded part solution for your application. We welcome the opportunity to provide you with exceptional quality, unparalleled service, and cost-effective solutions.