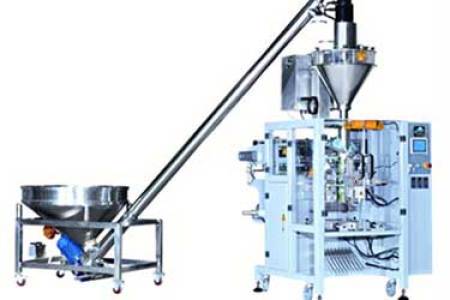

This Auger Type FFS (Form-Fill-Seal) machine is a robust and efficient solution for automated filling and sealing of a wide range of free-flowing products. Designed for high-volume production environments, this machine delivers exceptional speed, precision, and reliability, minimizing downtime and maximizing output.

Key Features & Benefits:

Applications:

Ideal for packaging a wide range of free-flowing products, including:

Technical Specifications: (Specific specifications will vary depending on model and configuration. Contact us for detailed specifications.)

Contact us today to discuss your specific packaging needs and receive a customized quote. We will help you determine the optimal Auger Type FFS Machine configuration to maximize your production efficiency and profitability.