Description

Non-Free-Flowing Products: Handling Difficult Materials with Ease

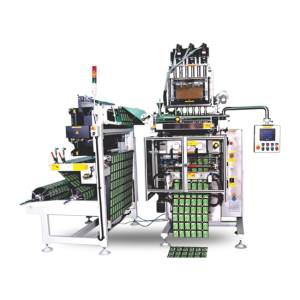

Many industrial processes rely on the efficient handling of materials, but not all materials cooperate. Non-free-flowing products, characterized by their tendency to clump, cake, or exhibit high internal friction, present significant challenges in transportation, processing, and storage. Our range of solutions tackles these challenges head-on, ensuring smooth operation and maximizing efficiency.

What are Non-Free-Flowing Products?

These materials resist gravity-driven flow, leading to difficulties in:

- Feeding: Consistent feeding into processing equipment is difficult, leading to inconsistent product quality and potential equipment damage.

- Transferring: Moving these materials between storage and processing areas can be slow and labor-intensive.

- Dispensing: Accurate and reliable dispensing is challenging, leading to waste and inaccuracies.

- Storage: Proper storage is crucial to prevent caking and clumping, requiring specialized techniques and infrastructure.

Our Solutions:

We offer a comprehensive range of products designed to address the unique challenges of handling non-free-flowing materials:

- Vibratory Feeders: Utilize vibration to break up clumps and promote consistent material flow. Our feeders are available in a range of sizes and capacities to suit various applications, featuring adjustable vibration intensity for optimal performance with diverse materials. Options include sanitary designs for food and pharmaceutical applications.

- Auger Conveyors: Ideal for transporting materials horizontally or at a slight incline. The rotating auger effectively moves material even with high levels of cohesive forces. We offer a variety of auger designs tailored to specific material properties and flow characteristics.

- Air Assist Systems: Introduce controlled airflows to fluidize the material, reducing friction and improving flowability. This gentle approach minimizes material degradation and is suitable for sensitive products.

- Material Handling Additives: Flow-enhancing agents can be incorporated directly into the material to improve its flowability. We offer a selection of additives tailored for different material types, ensuring optimal results without compromising product integrity. Our experts can assist in selecting the most suitable additive for your specific application.

- Custom Solutions: For exceptionally challenging materials or unique process requirements, we offer bespoke solutions tailored to your specific needs. Our engineering team works closely with clients to design and implement optimal material handling systems.

Benefits of Choosing Our Solutions:

- Improved Efficiency: Faster and more consistent material flow translates to increased throughput and reduced downtime.

- Reduced Waste: Accurate dispensing and minimized material degradation lead to less waste and lower production costs.

- Enhanced Product Quality: Consistent material flow ensures uniform processing and improved product consistency.

- Increased Safety: Our systems are designed with safety in mind, minimizing the risk of operator injury and equipment damage.

- Extended Equipment Lifespan: Reduced wear and tear on equipment due to smoother material flow extends its operational lifespan.

Contact Us Today:

We're committed to providing you with the best solutions for handling your non-free-flowing products. Contact our team of experts to discuss your specific needs and receive a customized solution. We'll help you choose the most efficient and cost-effective approach to managing your challenging materials.