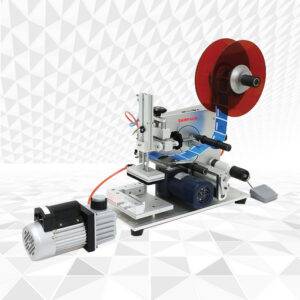

Revolutionize your packaging process with the XLM-5000 Automatic Labelling Machine. Designed for efficiency and precision, the XLM-5000 seamlessly integrates into your production line, significantly boosting output and minimizing manual labor. Ideal for a wide range of industries, from food and beverage to pharmaceuticals and cosmetics, this machine ensures consistent, accurate label placement every time.

Key Features:

Technical Specifications:

Benefits:

Contact us today to learn more about the XLM-5000 Automatic Labelling Machine and how it can transform your packaging process. Request a quote or schedule a demonstration.