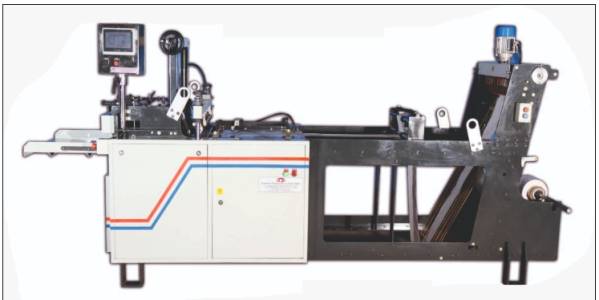

Revolutionize your packaging process with our state-of-the-art Bottom Seal Bag Making Machine. This robust and reliable machine offers unparalleled speed and precision for producing high-quality bottom seal bags, ideal for a wide range of applications, including food, pet food, chemicals, and more. Designed for both ease of use and maximum output, this machine is a valuable asset for businesses of all sizes looking to streamline their packaging operations.

Key Features & Benefits:

Technical Specifications:

(Specific specifications will vary depending on the model. Please contact us for detailed information on a specific configuration.)

Applications:

Investment & Return:

Investing in our Bottom Seal Bag Making Machine represents a significant enhancement to your packaging operation. The increased production speed, reduced labor costs, and improved product protection translate to a rapid return on investment and a significant competitive advantage.

Contact us today for a personalized consultation and to learn more about how our Bottom Seal Bag Making Machine can meet your specific packaging needs.