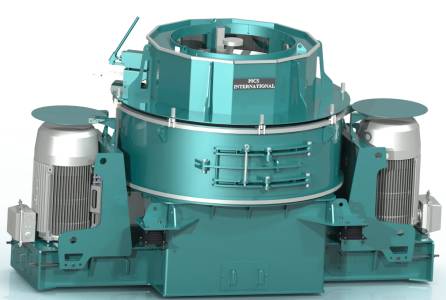

The Vertical Shaft Impactor (VSI) crusher is a high-performance, efficient machine designed for the size reduction of a wide variety of materials. Unlike traditional impact crushers, the VSI utilizes a unique vertical shaft and centrifugal force to achieve superior crushing results with minimal wear and tear. This results in a high-quality, cubical product ideal for numerous applications.

Key Features & Benefits:

Technical Specifications (Example - will vary based on model):

Applications:

Contact us today to learn more about how our Vertical Shaft Impactor can enhance your material processing operation and improve your bottom line. [Insert contact information here]