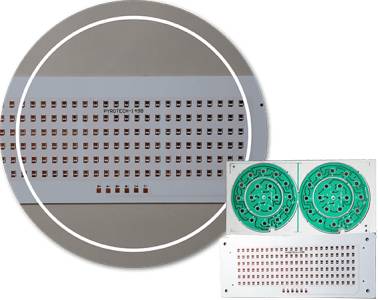

Metal core printed circuit boards (MCPCBs) represent a significant advancement in PCB technology, offering superior thermal management, high-frequency performance, and exceptional mechanical stability compared to traditional FR4 boards. These boards are ideal for applications requiring robust performance under challenging conditions.

Key Features and Benefits:

Applications:

Metal core PCBs are widely used in a variety of demanding applications, including:

Material Specifications (Examples – Customizable):

Why Choose Our Metal Core PCBs?

We utilize state-of-the-art manufacturing techniques and rigorous quality control measures to ensure that our MCPCBs meet the highest industry standards. Our experienced engineering team provides expert support throughout the design and manufacturing process, helping you achieve optimal performance and reliability for your application. Contact us today to discuss your project requirements and learn how our metal core PCBs can benefit your next design.