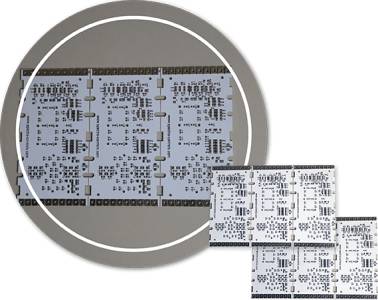

Aluminum Printed Circuit Boards (PCBs) represent a significant advancement in PCB technology, offering superior thermal management capabilities compared to traditional FR4 PCBs. Ideal for high-power applications where heat dissipation is critical, these boards provide enhanced reliability and extended lifespan.

Key Features & Benefits:

Specifications (Typical, can vary based on customization):

Choosing the Right Aluminum PCB:

The optimal aluminum PCB for your application depends on several factors, including power requirements, operating temperature, environmental conditions, and component layout. We offer design support and consultation to help you select the ideal solution. Please contact us with your project specifications for a personalized quote and lead time estimate.

Contact us today to discuss your high-power PCB needs!