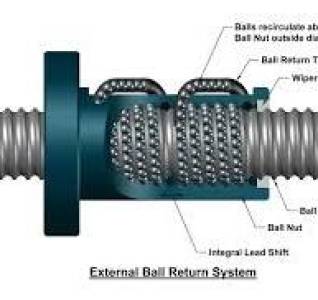

Ball screws, also known as ball lead screws, are electromechanical devices that translate rotary motion into linear motion with exceptional efficiency and precision. They are a crucial component in a wide range of applications demanding accurate and repeatable linear movement, offering superior performance compared to traditional lead screws or hydraulic/pneumatic systems.

Key Features & Benefits:

Specifications & Selection Considerations:

When selecting a ball screw, several key specifications must be considered:

Applications:

Ball screws are widely used in numerous industries and applications, including:

Maintenance:

Regular lubrication is crucial for maintaining the efficiency and lifespan of ball screws. The frequency of lubrication will depend on the operating conditions and load. Proper installation and alignment are also essential to ensure optimal performance and longevity.

Contact us today to discuss your specific application requirements and find the perfect ball screw solution for your needs.