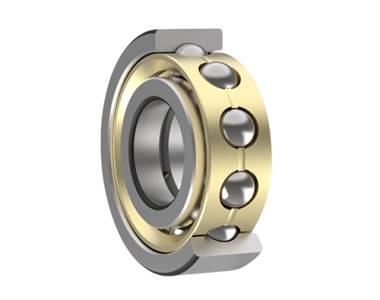

Four-point contact ball bearings are high-precision components engineered for applications demanding exceptional axial and radial load capacity, along with superior stiffness and accuracy. Unlike single-row or double-row bearings, these bearings provide contact at four points on the balls, distributing the load more effectively and significantly improving performance characteristics.

Key Features & Benefits:

Technical Specifications (Typical - Varies by Model):

Selection Considerations:

Choosing the right four-point contact ball bearing requires careful consideration of several factors including:

Conclusion:

Four-point contact ball bearings provide a superior solution for applications demanding high load capacity, precision, and rigidity. Their compact design, bi-directional thrust capability, and excellent performance characteristics make them a preferred choice across various industries. Consult our detailed specifications and engineering guides to select the optimal bearing for your specific application needs.