Description

FRP Sheets: Lightweight, Durable, and Versatile Solutions

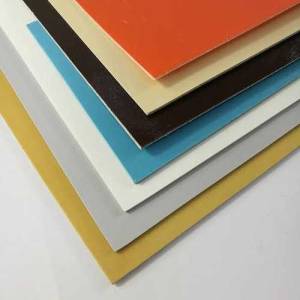

Introducing high-performance Fiber Reinforced Polymer (FRP) sheets – the ideal material for a wide range of applications requiring strength, durability, and lightweight design.

FRP sheets, also known as GRP (Glass Reinforced Polymer) sheets, are composite materials consisting of strong fibers (typically glass, carbon, or aramid) embedded in a resin matrix (usually polyester, vinyl ester, or epoxy). This unique construction results in a material that boasts exceptional properties, surpassing many traditional materials like wood, steel, and aluminum in several key areas.

Key Features & Benefits:

- Exceptional Strength-to-Weight Ratio: FRP sheets offer significantly higher strength compared to their weight, making them ideal for applications where weight reduction is crucial. This translates to lower transportation costs, easier handling, and reduced structural support requirements.

- High Durability & Longevity: Resistant to corrosion, rot, and many chemicals, FRP sheets maintain their structural integrity and appearance over extended periods, even in harsh environments. They are unaffected by moisture, making them perfect for outdoor applications.

- Corrosion Resistance: Unlike steel or aluminum, FRP sheets are completely impervious to rust and corrosion, eliminating costly maintenance and replacement associated with traditional materials. This makes them particularly suitable for marine, chemical, and industrial applications.

- Design Flexibility: Available in a variety of colors, thicknesses, and finishes, FRP sheets offer unparalleled design flexibility. They can be easily cut, shaped, and fabricated to meet specific project requirements.

- Low Maintenance: Their inherent durability significantly reduces the need for maintenance and repairs, resulting in long-term cost savings.

- UV Resistance: Many FRP sheet formulations offer excellent resistance to ultraviolet (UV) radiation, preventing degradation and discoloration from prolonged sun exposure.

- Insulating Properties: FRP sheets offer some level of thermal insulation, helping to reduce energy consumption in certain applications. The level of insulation varies depending on the core material and sheet construction.

Applications:

FRP sheets find application in a vast range of industries and projects, including:

- Construction: Roofing, cladding, wall panels, walkways, and structural components.

- Marine: Boat decks, hulls, bulkheads, and other marine structures.

- Chemical Processing: Chemical storage tanks, lining for corrosive environments.

- Transportation: Truck bodies, train cars, and other transportation applications.

- Industrial: Machine guards, structural supports, and containment systems.

- Renewable Energy: Solar panel mounting structures, wind turbine components.

Specifications (may vary depending on manufacturer and type):

- Thickness: Available in various thicknesses to suit different load requirements.

- Surface Finish: Smooth, textured, or patterned finishes are available.

- Color: A wide range of colors can be customized to match design aesthetics.

- Resin Type: Polyester, vinyl ester, or epoxy resins are commonly used.

- Fiber Type: Glass fiber is the most common, but carbon and aramid fibers are also used for specialized applications.

Choosing the Right FRP Sheet:

The optimal choice of FRP sheet depends on the specific application and required performance characteristics. Factors to consider include:

- Strength requirements: Load bearing capacity and desired stiffness.

- Chemical resistance: Exposure to specific chemicals or environments.

- UV exposure: Duration and intensity of sunlight exposure.

- Temperature range: Operating temperature fluctuations.

Contact us today to discuss your project requirements and select the perfect FRP sheet solution for your needs. We offer expert advice and competitive pricing.