Description

Polyester Resins: High-Performance Solutions for Diverse Applications

Polyester resins are versatile thermosetting polymers renowned for their exceptional strength, durability, and ease of processing. These resins, formed through the polymerization of unsaturated polyester acids and polyols, offer a wide range of properties customizable through careful formulation. They are widely used in various industries for creating strong, lightweight, and corrosion-resistant components.

Key Features & Benefits:

- High Strength-to-Weight Ratio: Polyester resins deliver excellent mechanical properties, providing high strength and stiffness while maintaining a relatively low weight. This makes them ideal for applications where weight reduction is crucial.

- Superior Durability & Longevity: Resistant to many chemicals, weathering, and abrasion, polyester resins offer long-lasting performance even in harsh environments. This ensures extended lifespan for products and components.

- Excellent Corrosion Resistance: Providing a robust barrier against corrosion, polyester resins are frequently used in protective coatings and in the construction of components exposed to corrosive elements.

- Easy Processing & Moldability: Polyester resins can be easily processed using various methods including hand lay-up, spray-up, filament winding, pultrusion, and injection molding. This versatility makes them suitable for a broad range of manufacturing processes.

- Cost-Effectiveness: Compared to many other high-performance polymers, polyester resins offer a competitive cost advantage, making them an economically viable solution for large-scale projects.

- Customization Options: The properties of polyester resins can be tailored through the addition of fillers, pigments, and other additives. This allows for the fine-tuning of characteristics such as flexibility, impact resistance, and color.

Types of Polyester Resins:

Several types of polyester resins exist, categorized based on their specific properties and applications:

- Orthophthalic Resins: These are the most common type, offering a good balance of cost and performance. They are widely used in general-purpose applications.

- Isophthalic Resins: Known for their enhanced chemical resistance and superior mechanical properties compared to orthophthalic resins, they are often preferred in demanding applications.

- Bisphenol A Resins: Exhibiting superior chemical resistance and heat resistance, these resins are employed in applications requiring exceptional durability.

- Vinyl Ester Resins: A hybrid between polyester and epoxy resins, vinyl esters provide increased chemical resistance and impact strength. They are often used in marine and corrosive environments.

Applications:

Polyester resins find applications in a vast array of industries and products, including:

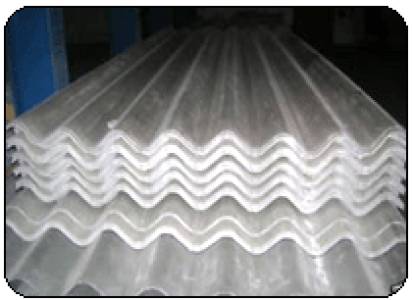

- Fiberglass Reinforced Plastics (FRP): A major application, polyester resins are the primary matrix material in FRP composites used in construction, automotive, marine, and wind energy sectors.

- Coatings & Protective Coatings: Their excellent corrosion and weather resistance make them suitable for protective coatings on metal surfaces, pipes, and other structures.

- Automotive Parts: Used in various automotive components, offering lightweight and durable solutions.

- Marine Applications: Polyester resins are extensively used in boat hulls, decks, and other marine structures due to their resistance to saltwater corrosion.

- Pipes & Tanks: Used in the manufacturing of chemical-resistant pipes and storage tanks.

Safety Precautions:

While polyester resins offer many benefits, safety precautions must be followed during handling and processing. These include wearing appropriate personal protective equipment (PPE), ensuring adequate ventilation, and following the manufacturer's safety data sheet (SDS).

This detailed description provides a comprehensive overview of polyester resins, highlighting their key properties, types, applications, and safety considerations. For specific product information and technical data, please refer to the manufacturer's specifications.