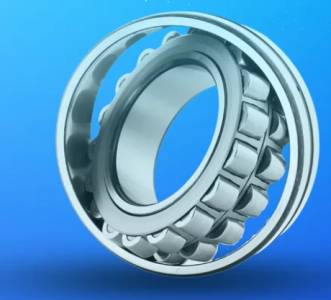

Roller bearings are essential machine elements designed to reduce friction and support radial loads (loads applied perpendicular to the shaft). They provide significantly higher load-carrying capacity compared to ball bearings, making them ideal for heavy-duty applications and high-speed operations where durability and longevity are paramount. This superior performance comes from the use of cylindrical or tapered rollers that distribute the load over a larger contact area.

Types of Roller Bearings:

We offer a wide range of roller bearings to meet diverse application needs:

Key Features & Benefits:

Applications:

Roller bearings are used extensively in a wide range of industries and applications, including:

Choosing the Right Roller Bearing:

Selecting the appropriate roller bearing depends on several factors, including:

Contact us today to discuss your specific application requirements and let our experts help you choose the optimal roller bearings for your needs. We offer a comprehensive selection of high-quality roller bearings, competitive pricing, and prompt delivery.