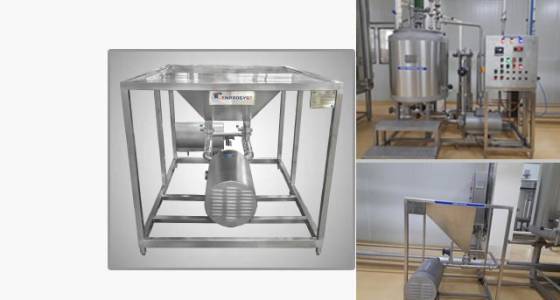

This high-quality Sugar Preparation Unit is designed for efficient and consistent preparation of sugar solutions for various industrial applications, including food and beverage production, pharmaceutical manufacturing, and chemical processing. Built for durability and ease of use, this unit streamlines the sugar dissolution process, ensuring optimal quality and minimizing downtime.

Key Features:

Specifications:

Applications:

Contact us today to learn more about our Sugar Preparation Unit and how it can optimize your sugar processing operations. [Include Contact Information]