The Auger Filler is a versatile and reliable machine designed for the precise and efficient filling of powders and granular materials into various containers. Whether you're filling bags, bottles, jars, or other receptacles, our Auger Filler provides consistent fill weights and minimizes waste, boosting your production efficiency and improving product quality.

Key Features:

Benefits:

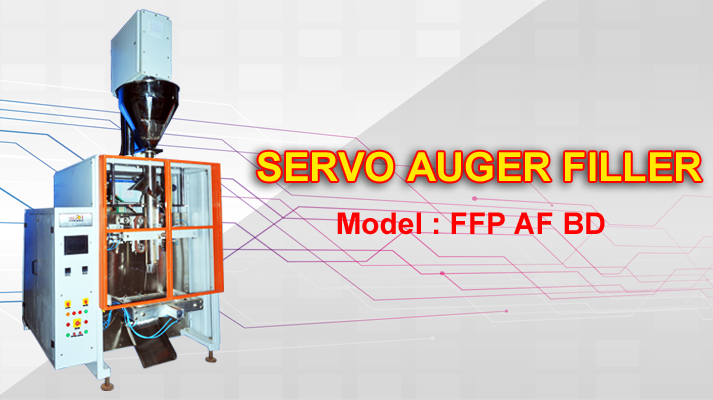

Specifications: (Specific specifications will vary depending on model. Contact us for detailed information on specific models.)

Contact us today to learn more about our Auger Filler and find the perfect model to meet your specific filling requirements.