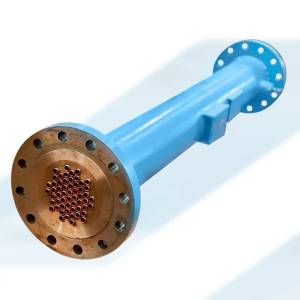

Maximize your heat transfer applications with our precision-engineered tube bundles. Designed for superior performance and longevity, our tube bundles are manufactured using high-quality materials and advanced fabrication techniques to meet the most demanding industrial requirements. Whether you need replacement bundles for existing systems or components for new designs, we offer customizable solutions tailored to your specific needs.

Key Features & Benefits:

Specifications (Example - Customizable):

Ordering Information:

To obtain a quote or place an order, please provide the following information:

Contact us today to discuss your specific requirements and let our experts help you select the perfect tube bundle for your application.