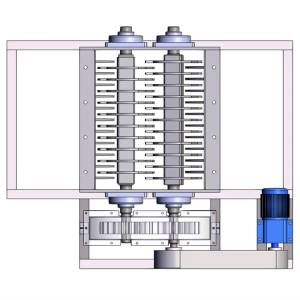

Tired of battling stubborn lumps and agglomerates in your materials? The LUMP BREAKER is the ultimate solution for efficient and reliable size reduction, transforming bulky, solidified materials into easily manageable particles. Designed for demanding applications across various industries, the LUMP BREAKER delivers superior performance and unmatched durability.

Unmatched Performance & Versatility:

Key Specifications (Example - Adjust based on specific model):

| Specification | Value |

|---|---|

| Model | LUMP BREAKER 5000 |

| Maximum Input Size | 100mm |

| Output Size Range | 5-20mm |

| Throughput Capacity | 5 tons/hour |

| Power Requirement | 220V/440V |

| Motor Power | 75 kW |

| Dimensions (L x W x H) | 2m x 1.5m x 1.8m |

| Weight | 2500 kg |

Benefits of Choosing the LUMP BREAKER:

Contact us today to discuss your specific lump breaking needs and find the perfect LUMP BREAKER solution for your application.

[Include contact information: Phone number, email address, website]