Maximize Efficiency and Minimize Costs with Our Advanced Multi-Stage Evaporator

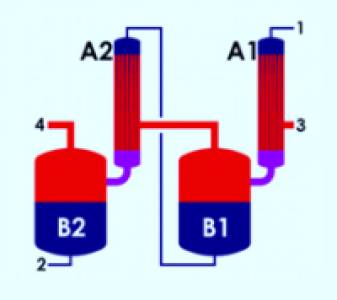

Our robust multi-stage evaporator is engineered for efficient and cost-effective concentration and evaporation of various liquids. Utilizing a sophisticated multi-stage design, this system excels in handling large volumes of liquid while minimizing energy consumption and operational costs compared to single-stage evaporators. Ideal for a wide range of industries, our evaporator ensures optimal performance and high-quality output.

Key Features and Benefits:

Technical Specifications: (This section should be populated with specific details based on the product offerings. Examples below)

Contact us today to discuss your specific evaporation needs and receive a customized quote. Our experienced engineers will work with you to design and implement the optimal multi-stage evaporation solution for your process.