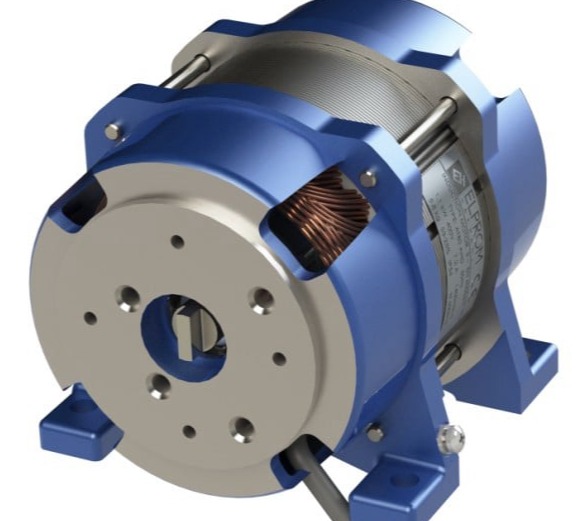

Oil-submerged motors provide a robust and dependable solution for applications requiring high performance in challenging environments. These motors offer superior protection against harsh conditions, ensuring long-term operation and minimizing downtime. This description details the key features, benefits, and applications of our range of oil-submerged motors.

Oil-submerged motors are ideal for a wide variety of applications, including:

Contact us today to discuss your specific application requirements and find the perfect oil-submerged motor for your needs.