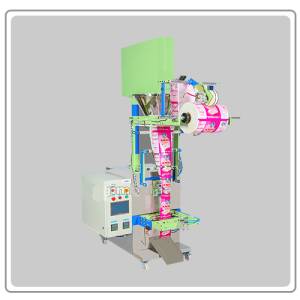

This high-performance automatic powder packing machine is engineered for efficient and precise packaging of various powdered products, from food ingredients and pharmaceuticals to chemicals and cosmetics. Its robust design and advanced features ensure consistent output and minimize waste, making it an ideal investment for businesses of all sizes seeking to streamline their production processes.

For more information or to request a quote, please contact us at [Your Contact Information]. We are happy to answer any questions and discuss your specific packaging requirements.