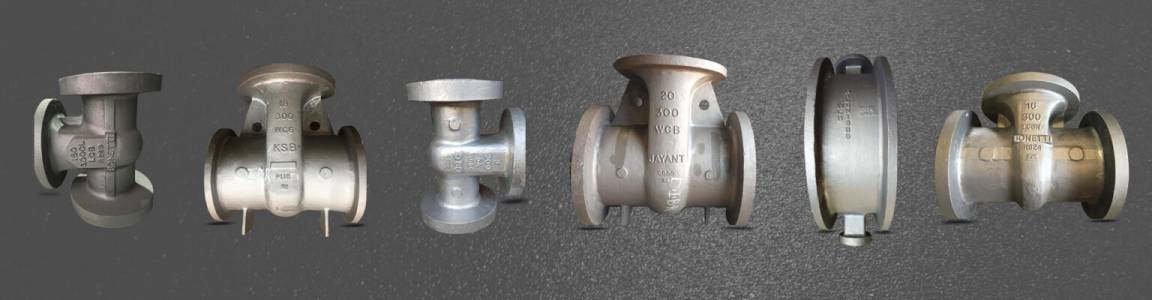

Our valve castings are meticulously crafted using advanced casting techniques to deliver superior performance, durability, and reliability across a wide range of applications. We offer a diverse selection of materials and sizes to meet your specific project needs. Whether you require high-pressure resistance, corrosion resistance, or exceptional thermal stability, we have the perfect valve casting solution.

Key Features and Benefits: