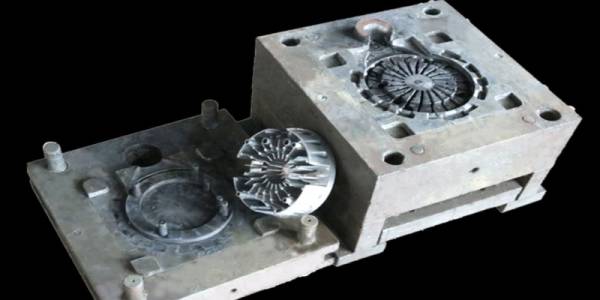

Elevate your production with our meticulously crafted die and moulds, engineered for exceptional performance and longevity. We offer a comprehensive range of custom-designed and standard die and mould solutions to meet the diverse needs of various industries. From intricate components to high-volume production runs, our expertise ensures consistent, high-quality results.

Our die and moulds serve a wide range of industries, including: