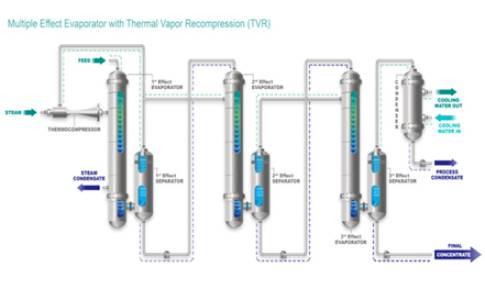

Our Multiple Effect Evaporator (MEE) represents a significant advancement in evaporation technology, offering superior efficiency and cost-effectiveness compared to single-effect evaporators. Designed for a wide range of industries, our MEEs deliver optimal performance in concentrating liquids and recovering valuable components.

Key Features & Benefits:

Technical Specifications: (Specific details will be provided upon request based on your application requirements, including):

Why Choose Our MEE?

We provide comprehensive solutions, including design, engineering, fabrication, installation, commissioning, and after-sales service. Our experienced team offers expert support throughout the entire process, ensuring optimal performance and a seamless integration into your existing production line. Contact us today to discuss your specific requirements and receive a tailored proposal.