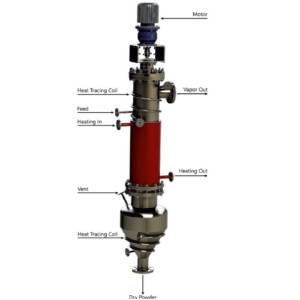

Revolutionize your drying processes with our advanced Agitated Thin Film Dryer. Designed for efficient and gentle drying of heat-sensitive, viscous, and shear-sensitive materials, our dryer offers unparalleled control and superior product quality. Whether you're processing pharmaceuticals, chemicals, food products, or specialty materials, our system is engineered for optimal performance and scalability.

Key Features & Benefits:

Technical Specifications (Example - Specifics will vary by model):

Applications:

Contact us today to discuss your specific drying needs and learn how our Agitated Thin Film Dryer can optimize your production process and improve your bottom line. We offer customized solutions and comprehensive after-sales support to ensure your success.