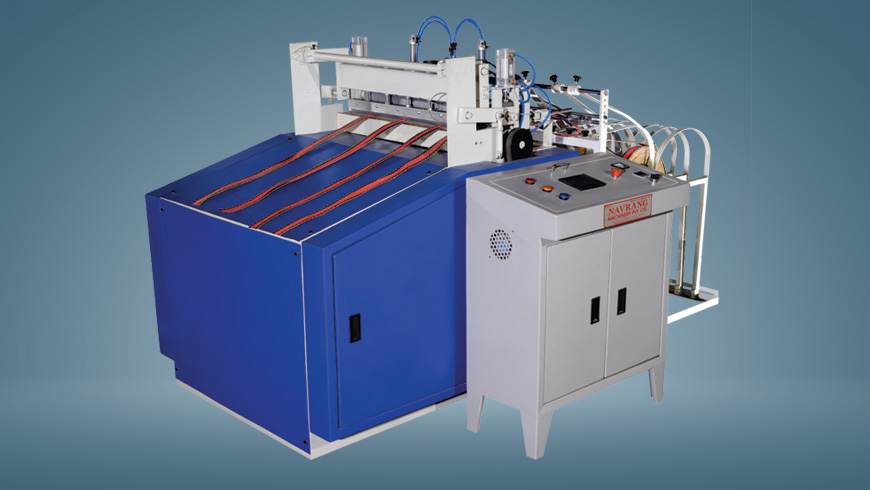

Revolutionize your webbing and belt production with our cutting-edge Webbing (Belt) Cutting Machine. This industrial-grade machine delivers unparalleled speed, accuracy, and efficiency, significantly boosting your output and minimizing waste. Designed for heavy-duty use, this machine is the perfect solution for manufacturers of seat belts, luggage straps, pet harnesses, and other webbing products.

Key Features:

Specifications:

Benefits:

Optional Accessories:

Contact us today for a quote and to learn more about how our Webbing (Belt) Cutting Machine can transform your production process!