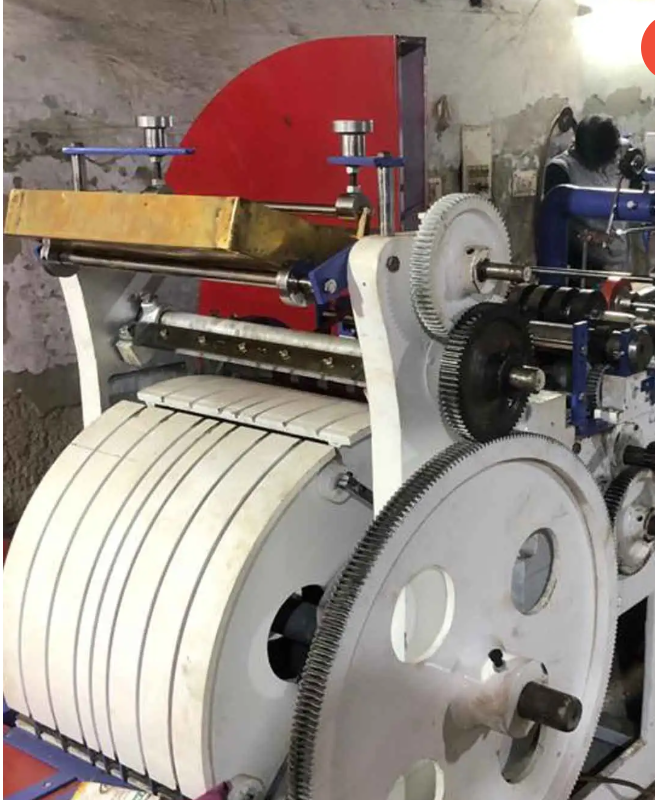

Revolutionize your packaging process with our cutting-edge automatic paper bag making machine! This robust and efficient machine is designed for high-volume production of high-quality paper bags, perfect for a wide range of applications, from grocery stores and retail shops to industrial packaging needs. Built with durability and precision in mind, this machine offers unparalleled performance and minimizes downtime, maximizing your return on investment.

Key Features:

Technical Specifications:

Benefits:

Warranty: [Specify warranty period and details]

Contact us today for a quote and to learn more about how our Paper Bag Making Machine can benefit your business! [Include contact information: Phone number, email address, website]