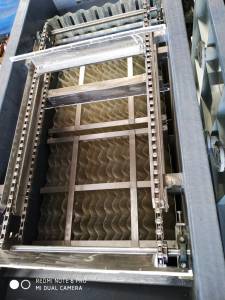

The Cross Flow Separator (CFS) offers a highly efficient and cost-effective solution for separating liquids and solids, or immiscible liquids, from process streams. Unlike conventional gravity settling techniques, the CFS utilizes centrifugal force to achieve rapid and complete separation, even with challenging feedstocks containing fine particles or emulsions. This advanced technology minimizes downtime and maximizes throughput, making it an ideal choice for a wide range of industries.

(Note: Specific specifications will vary depending on the model and configuration. Please contact us for details.)

The Cross Flow Separator finds applications in numerous industries, including but not limited to:

For more information, detailed specifications, or a customized solution tailored to your specific needs, please contact our sales team. We are happy to discuss your application and provide a tailored quote.