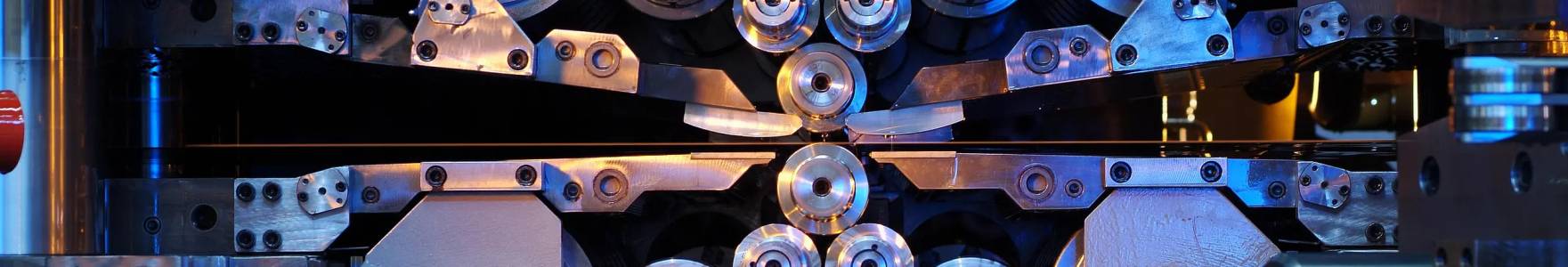

Our range of cold rolling mills offers unparalleled precision and efficiency for the production of high-quality metal sheets and strips. Designed for demanding applications across diverse industries, these mills deliver exceptional performance, minimizing material waste and maximizing output. Whether you're processing stainless steel, aluminum, copper, or other non-ferrous metals, our cold rolling mills provide the superior control and consistency you need.

Key Features & Benefits:

Available Models:

We offer a range of cold rolling mills to meet various production scales and material requirements:

Optional Features:

Contact us today to discuss your specific needs and receive a customized quotation. Our team of experts will assist you in selecting the perfect cold rolling mill solution for your business.

(Include images/videos of the mills in action here)