High-Density Polyethylene (HDPE) pipe offers a robust and versatile solution for a wide range of applications, boasting superior performance characteristics compared to traditional materials like steel or cast iron. This description details the key features and benefits of HDPE pipe, making it the ideal choice for various industries and projects.

HDPE pipe finds applications across diverse sectors:

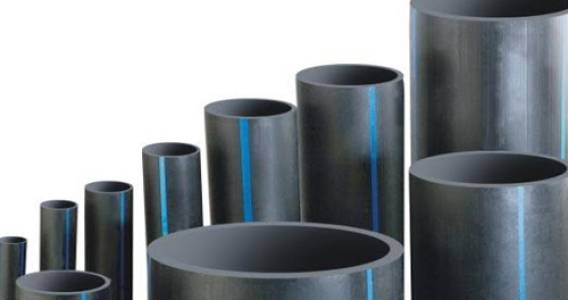

HDPE pipe is available in various sizes, schedules (pressure ratings), and configurations to meet specific project requirements. These include:

Selecting the appropriate HDPE pipe requires considering factors such as:

Consulting with a qualified engineer or HDPE pipe specialist is crucial to ensure the selection of the optimal pipe for your specific project needs.

This information provides a comprehensive overview of HDPE pipe. For detailed specifications and technical data, please refer to the manufacturer's product literature.