Description

Lab Grade vs. Commercial Grade Chemicals: A Detailed Comparison

Choosing the right grade of chemical is crucial for the success of any experiment or process. The terms "lab grade" and "commercial grade" often appear, but their differences are significant and can impact your results, safety, and budget. This guide clarifies the key distinctions:

Lab Grade Chemicals

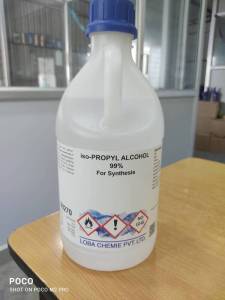

Definition: Lab grade chemicals, also known as reagent grade, are manufactured and purified to meet stringent standards for purity and consistency. They are specifically designed for use in analytical chemistry, research, and other applications where high accuracy and reliability are paramount.

Key Characteristics:

- High Purity: Lab grade chemicals boast exceptionally low levels of impurities. Specific impurity limits are defined by organizations like the American Chemical Society (ACS) and are often listed on the product label. These specifications ensure minimal interference in experiments and accurate results.

- Traceability & Documentation: Comprehensive documentation accompanies lab grade chemicals, including certificates of analysis (CoA) detailing the specific composition, purity levels, and testing methods used. This traceability is vital for maintaining the integrity of research and ensuring compliance with regulatory requirements.

- Consistent Quality: Manufacturers of lab grade chemicals adhere to rigorous quality control procedures to guarantee consistent quality and performance from batch to batch. This reliability is essential for reproducible experiments and dependable outcomes.

- Packaging & Handling: Lab grade chemicals are often packaged in specialized containers designed to prevent contamination and degradation, ensuring the integrity of the product throughout its shelf life.

- Cost: Due to the higher level of purity and stringent manufacturing processes, lab grade chemicals are typically more expensive than commercial grade chemicals.

Typical Applications:

- Analytical chemistry

- Scientific research

- Quality control testing

- Pharmaceutical development

- Food and beverage analysis

Commercial Grade Chemicals

Definition: Commercial grade chemicals are produced to meet specific industrial requirements rather than the stringent purity standards of lab grade chemicals. They are generally less expensive but may contain higher levels of impurities.

Key Characteristics:

- Lower Purity: Commercial grade chemicals have a wider range of acceptable impurity levels compared to lab grade chemicals. These impurities may not significantly affect their intended industrial applications, but they could be problematic for sensitive scientific experiments.

- Limited Documentation: While some basic information may be provided, commercial grade chemicals often lack the detailed documentation and CoAs associated with lab grade chemicals.

- Variable Quality: Due to less stringent quality control measures, the consistency of commercial grade chemicals can vary from batch to batch.

- Packaging & Handling: Packaging is typically less sophisticated than for lab grade chemicals, reflecting the lower purity requirements.

- Cost: Commercial grade chemicals are considerably less expensive than lab grade chemicals due to lower production costs and less rigorous quality control.

Typical Applications:

- Industrial manufacturing processes

- Large-scale chemical reactions

- Cleaning and sanitation

- Agricultural applications

Choosing the Right Grade:

The choice between lab grade and commercial grade chemicals depends heavily on the intended application. For applications requiring high accuracy, reliability, and traceability (such as scientific research or analytical testing), lab grade chemicals are essential. For industrial applications where high purity is less critical, commercial grade chemicals offer a cost-effective alternative. Using the wrong grade can lead to inaccurate results, compromised safety, and potential waste of resources. Always carefully consider the specific requirements of your project before making a purchase.