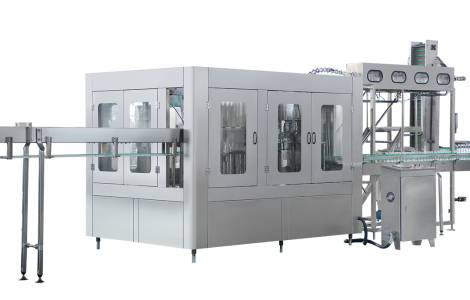

This fully automated rinsing, filling, and capping (RFC) machine represents a significant upgrade for your production line, offering unparalleled efficiency, hygiene, and precision in bottling liquids of various viscosities. Designed for high-volume operations, this machine streamlines the entire process from bottle cleaning to final sealing, minimizing manual intervention and maximizing output.

Key Features & Benefits:

Technical Specifications:

Optional Features:

Contact us today to discuss your specific bottling needs and receive a personalized quotation. We offer comprehensive installation, training, and after-sales support to ensure your smooth transition to automated bottling.