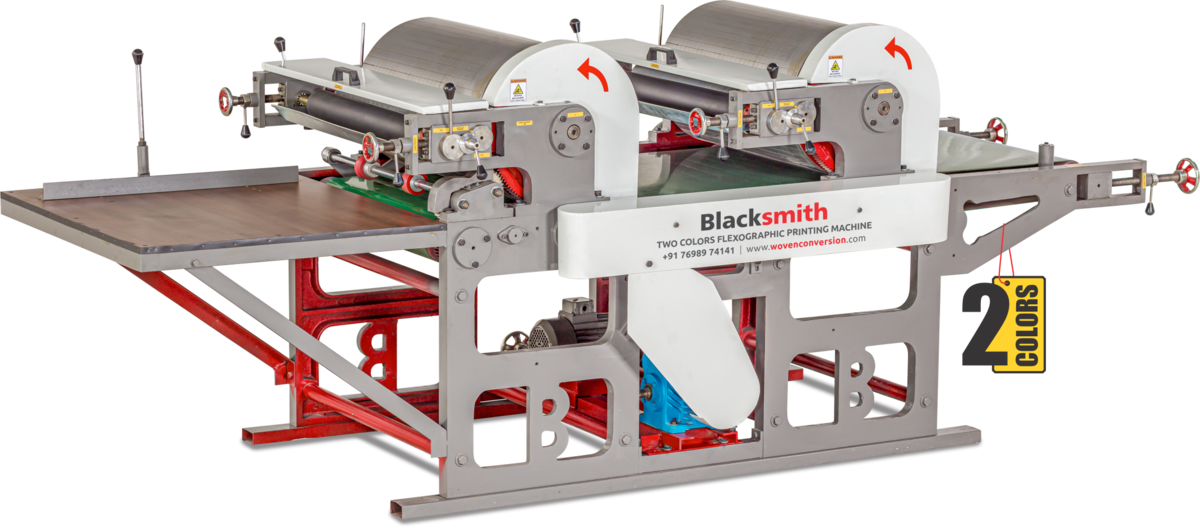

This robust and versatile Two Color Bag-to-Bag Flexo Printing Machine is designed for high-speed, high-quality printing directly onto various flexible packaging materials, including but not limited to:

Unleash the Power of Efficient & Vibrant Printing:

This machine streamlines your production process, eliminating the need for pre-printed film and significantly reducing waste. Direct-to-bag printing ensures cost savings and allows for on-demand customization, ideal for short-run projects and personalized designs.

Key Features & Specifications:

Benefits:

Ideal for:

Contact us today for a personalized quote and to discuss your specific requirements. We offer comprehensive installation, training, and after-sales support. (Include contact information here – phone number, email, website).