Ultrasonic liquid processing leverages the power of high-frequency sound waves to induce cavitation—the formation, growth, and implosive collapse of microscopic bubbles—within a liquid medium. This powerful phenomenon generates intense localized energy, leading to a wide range of beneficial effects across diverse industries. Our ultrasonic processors offer a precise and efficient method for enhancing various liquid-based processes.

Key Applications & Benefits:

Our Ultrasonic Liquid Processors:

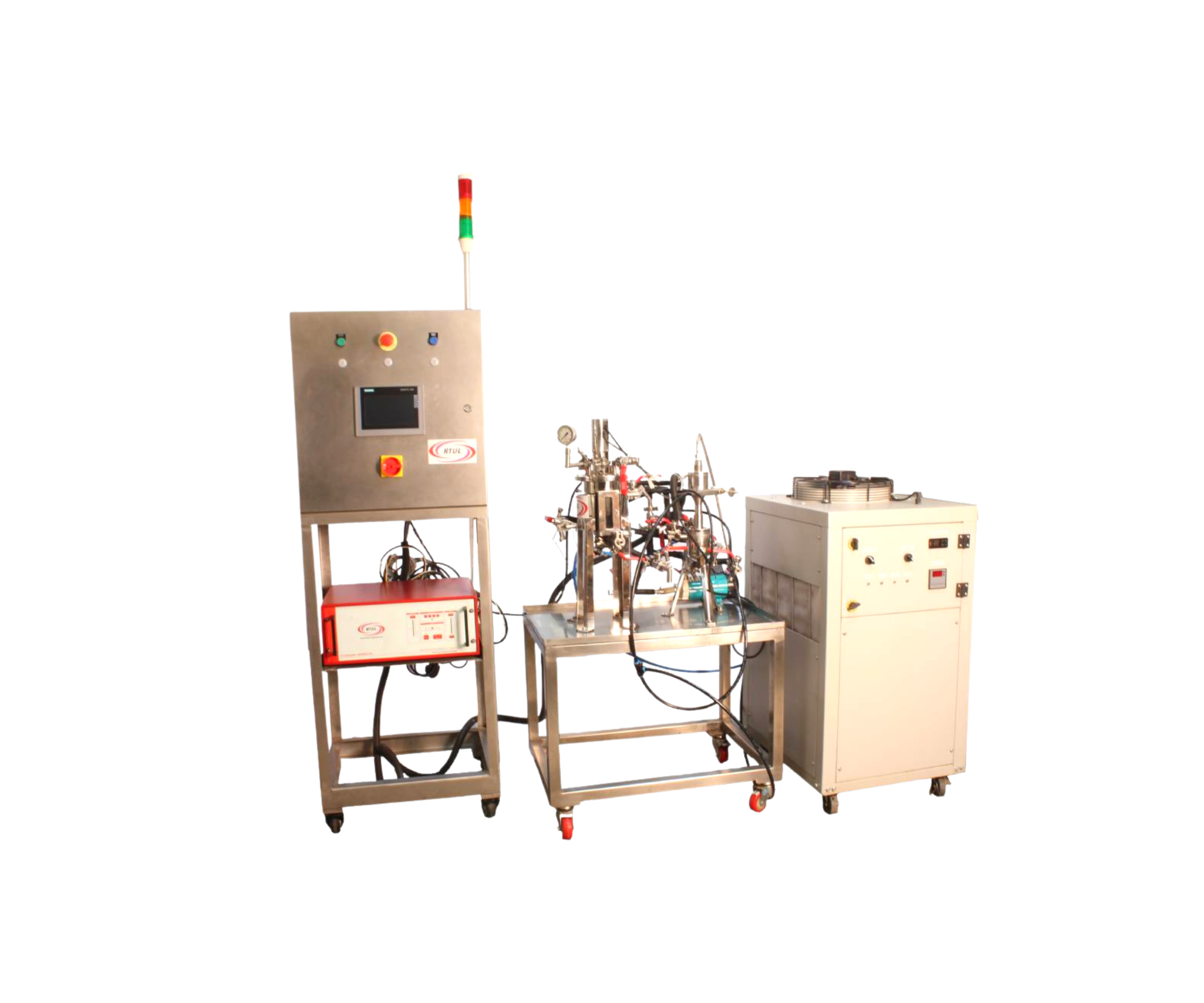

Our range of ultrasonic liquid processing systems offers flexibility and scalability to meet diverse application requirements:

Features & Specifications (Vary by Model):

Why Choose Our Ultrasonic Liquid Processors?

Contact us today to discuss your specific liquid processing needs and discover how ultrasonic technology can benefit your business.