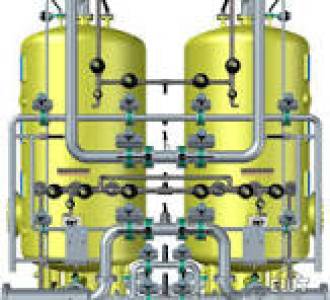

Mixed bed polishing units represent the pinnacle of water purification technology, delivering exceptionally pure water ideal for critical applications demanding the highest levels of purity. These units employ a powerful combination of strongly acidic cation and strongly basic anion exchange resins, meticulously blended in a single vessel, to remove virtually all remaining ionic impurities from pre-treated water.

Key Features & Benefits:

Technical Specifications (Typical - subject to customization):

Contact us today to discuss your specific requirements and receive a customized quote for a mixed bed polishing unit tailored to your application. Our expert team will help you select the optimal configuration to meet your water purity goals and budget.