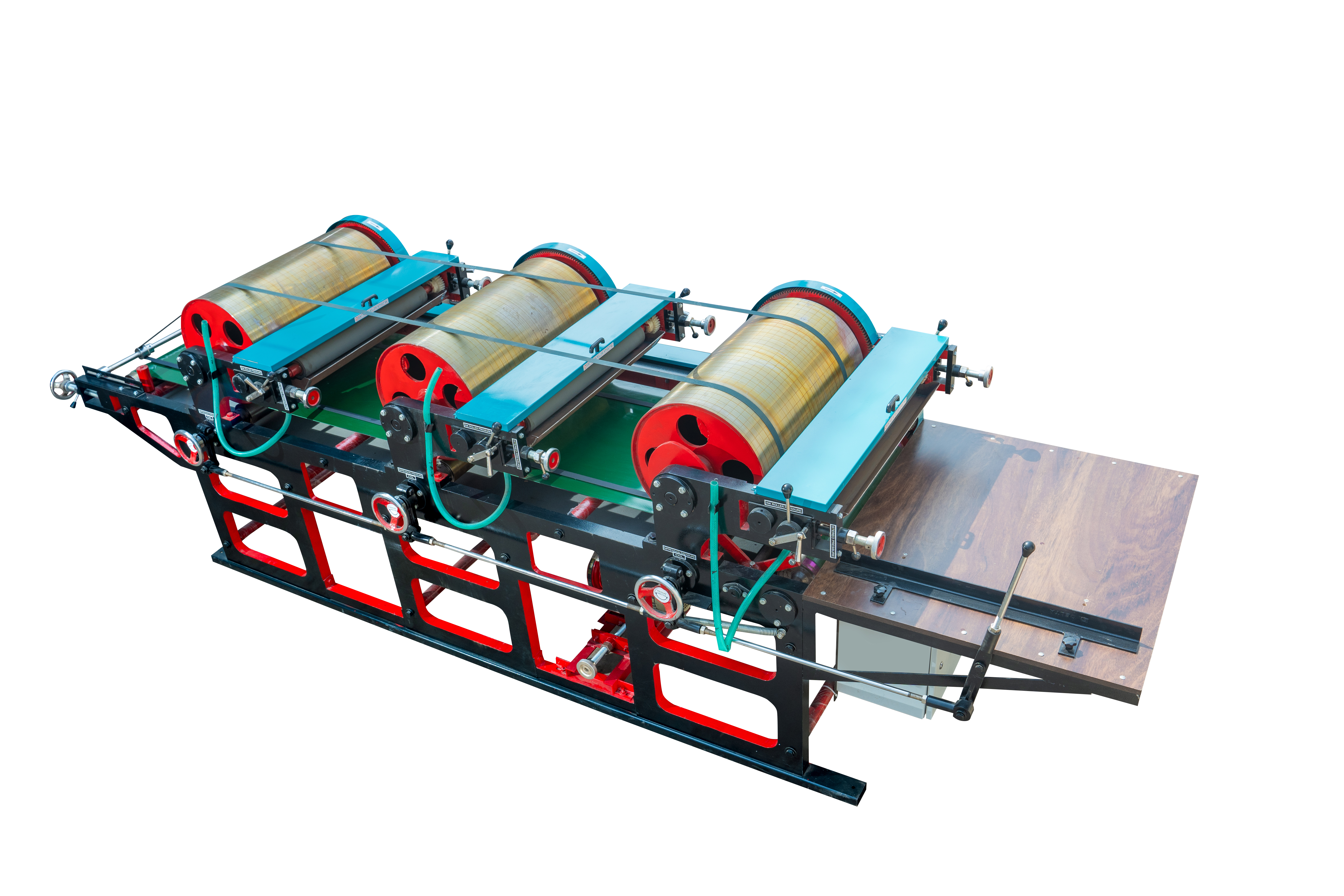

Revolutionize your printing process with the X-Series Flexographic Printing Machine, designed for superior quality, unmatched efficiency, and unparalleled versatility. This state-of-the-art machine is perfect for businesses demanding high-volume, high-quality printing on a wide range of flexible substrates.

Key Features & Benefits:

Versatile Substrate Handling: Process a broad spectrum of flexible materials, including but not limited to:

The machine's robust design ensures gentle handling of even the most delicate substrates, preventing damage and guaranteeing consistent print results.

Technical Specifications:

Contact us today to learn more about the X-Series Flexographic Printing Machine and discover how it can transform your printing operations. We offer comprehensive training and ongoing support to ensure your success.

[Include Contact Information: Phone number, email address, website]