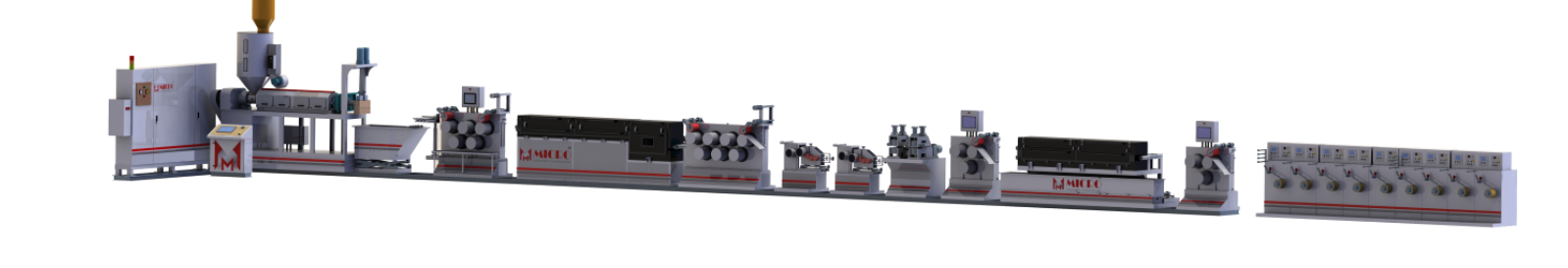

Revolutionize your packaging with the StrapPEX PP Box Strap Extrusion Line – a robust and efficient solution for producing high-quality polypropylene (PP) box strapping. This advanced system offers unparalleled versatility, superior output, and minimized operational costs, making it the ideal choice for businesses of all sizes seeking to streamline their packaging processes.

Key Features:

Benefits:

Specifications: (Specific specifications will be provided upon request based on your needs. This will include details on power requirements, dimensions, production capacity, etc.)

Contact us today to learn more about the StrapPEX PP Box Strap Extrusion Line and how it can transform your packaging operations. Our team of experts will be happy to answer your questions and help you select the optimal configuration to meet your specific requirements.