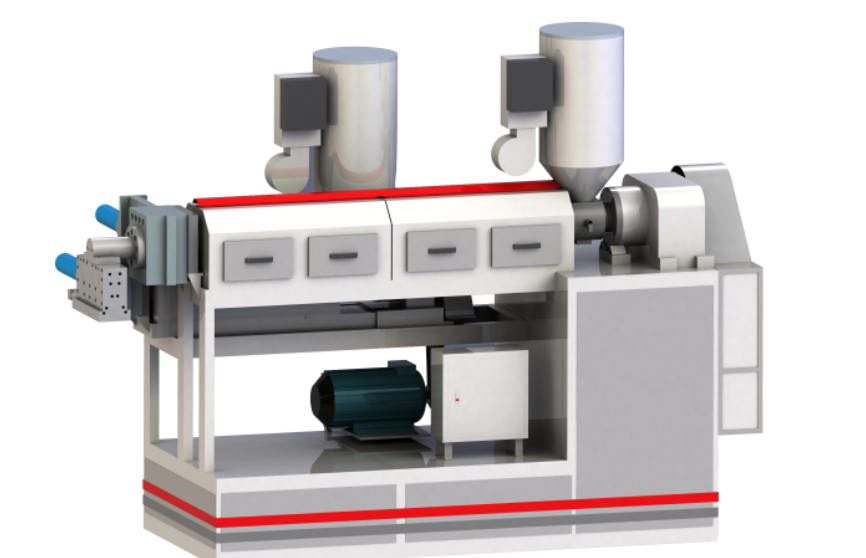

Revolutionize your strapping production with StrapCOAT, the advanced PP coating strap extrusion line designed for superior quality, efficiency, and versatility. This comprehensive system allows you to produce high-quality, coated polypropylene strapping with exceptional tensile strength, improved surface properties, and enhanced resistance to environmental factors.

Key Features & Benefits:

Technical Specifications: (Specific specifications will be provided upon request based on your requirements)

Contact Us:

Ready to elevate your strapping production? Contact our sales team today for a personalized consultation and a detailed quotation tailored to your specific needs. Let StrapCOAT help you achieve superior quality, increased efficiency, and greater profitability.