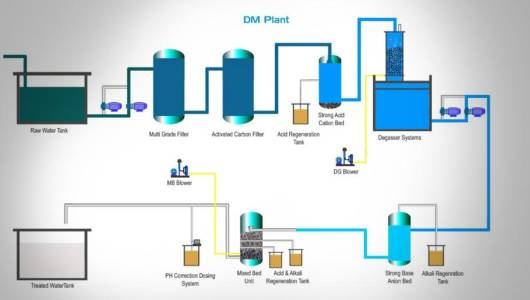

This comprehensive Demineralization Water Treatment Plant (DM Plant) delivers high-quality, ultra-pure water, ideal for various industrial and commercial applications demanding the highest level of purity. Our plants are engineered for optimal efficiency, reliability, and scalability, ensuring a consistent supply of demineralized water to meet your specific requirements.

Key Features & Benefits:

Specifications (Customizable):

Contact us today to discuss your specific requirements and receive a customized proposal for your Demineralization Water Treatment Plant.