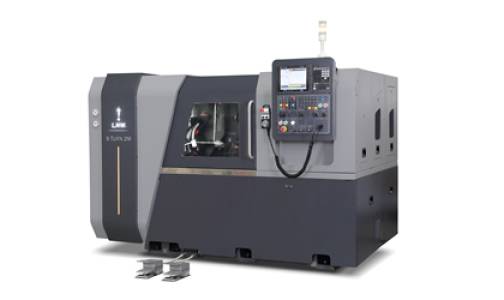

The TURNMILL CENTER represents a paradigm shift in machining capabilities, seamlessly integrating turning and milling operations into a single, highly efficient platform. This isn't just a combination of two machines; it's a sophisticated, fully integrated system designed for maximum productivity and precision. Eliminate the need for multiple setups, reduce lead times, and unlock unprecedented levels of accuracy with the TURNMILL CENTER.

Unmatched Versatility:

Advanced Technology for Superior Performance:

Key Benefits:

Ideal for:

Contact us today to learn more about how the TURNMILL CENTER can revolutionize your machining operations and unlock new levels of productivity and profitability.