Description

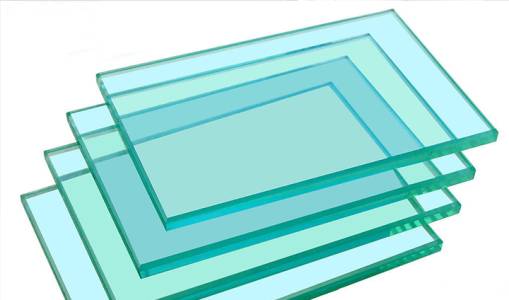

FLOAT GLASS: Superior Clarity and Precision for Diverse Applications

Float glass, also known as flat glass, is a type of glass produced by floating molten glass on a bed of molten tin. This innovative process results in a remarkably flat, smooth, and optically clear surface, making it ideal for a wide range of applications. Unlike older methods, float glass eliminates the need for extensive grinding and polishing, leading to superior quality and cost-effectiveness.

Key Features and Benefits:

- Exceptional Flatness and Smoothness: The unique manufacturing process ensures unparalleled flatness and smoothness, eliminating surface imperfections and providing a consistent, high-quality surface. This is crucial for applications requiring precise optical properties or a flawless aesthetic finish.

- Superior Optical Clarity: Float glass boasts exceptional transparency, allowing for maximum light transmission and minimal distortion. This clarity makes it perfect for windows, mirrors, and other applications where visual fidelity is paramount.

- High Dimensional Stability: Its inherent stability means minimal warping or distortion over time, ensuring consistent performance and longevity. This is vital for applications requiring precise dimensions, such as in architectural projects or scientific equipment.

- Versatile Thickness Options: Float glass is available in a wide range of thicknesses, from thin sheets ideal for picture frames to thick panes suitable for high-performance windows and automotive applications. This versatility allows for custom solutions tailored to specific needs.

- Excellent Chemical Resistance: Float glass is resistant to many chemicals and environmental factors, contributing to its durability and long lifespan. This makes it a reliable choice for both indoor and outdoor applications.

- Easy to Process: Float glass is relatively easy to cut, shape, and process further, allowing for flexibility in design and customization.

- Cost-Effective: While offering superior quality, float glass remains a cost-effective solution compared to other glass types, making it an economically viable choice for various projects.

Applications:

Float glass finds widespread application in numerous industries, including:

- Architectural: Windows, doors, curtain walls, facades, skylights

- Automotive: Windshields, side windows, rear windows, sunroofs

- Household: Mirrors, shower doors, tabletops, picture frames

- Electronics: Touchscreens, displays, protective covers

- Solar: Solar panels

- Scientific & Laboratory: Laboratory equipment, optical instruments

Specifications (Variable based on type and thickness):

- Thickness: Available in a wide range of thicknesses (e.g., 2mm to 25mm)

- Size: Custom sizes available, with standard sheet sizes varying by manufacturer.

- Color: Typically clear, but can be tinted or coated for specific properties (e.g., UV protection, energy efficiency).

- Surface Finish: Typically smooth and polished.

Choosing the Right Float Glass:

When selecting float glass, consider factors such as required thickness, desired optical properties, intended application, and budget. Contact our sales team for assistance in choosing the optimal float glass solution for your specific needs. We offer various types of float glass, including annealed, heat-strengthened, and tempered glass, each with its own distinct properties and applications.