Description

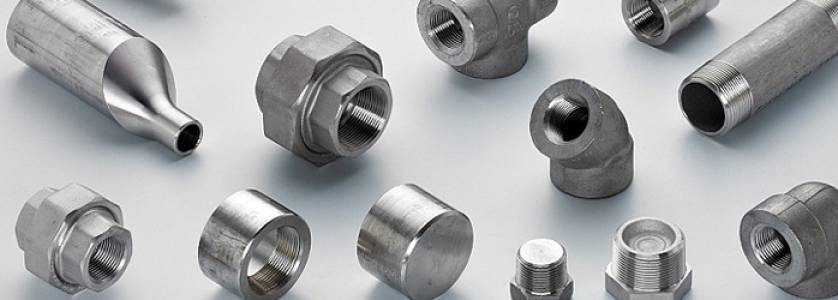

FORGED FITTING TYPE SOCKET WELD FITTINGS: Superior Strength and Reliability for High-Pressure Applications

Uncompromising Quality for Demanding Environments: Our Forged Fitting Type Socket Weld Fittings offer exceptional strength, durability, and reliability, making them ideal for high-pressure, high-temperature applications where performance is critical. Manufactured from premium materials and precision-forged for superior dimensional accuracy, these fittings provide a leak-free seal, ensuring the integrity of your system.

Key Features & Benefits:

- Forged Construction: Unlike cast fittings, our forged fittings boast superior mechanical properties, including higher tensile strength, yield strength, and impact resistance. This translates to increased durability and longevity, even under extreme operating conditions.

- Socket Weld Design: The socket weld design ensures a strong, reliable, and leak-free connection. The socket provides a large contact area for the weld, resulting in a superior weld integrity and minimizing the risk of leaks. This design is particularly advantageous in applications requiring high pressure and vibration resistance.

- Precise Dimensions: Our fittings are manufactured to exacting tolerances, ensuring a perfect fit with other components in your system. This precision minimizes installation challenges and promotes a smooth, efficient assembly process.

- Variety of Materials: Available in a range of high-quality materials including Carbon Steel (e.g., ASTM A105, A106), Stainless Steel (e.g., 304, 316), and Alloy Steel (specify your requirements), allowing you to select the optimal material for your specific application and environmental conditions. (Specific material certifications available upon request.)

- Wide Range of Sizes and Configurations: We offer a comprehensive selection of sizes and configurations to meet diverse application needs. This includes elbows, tees, crosses, reducers, couplings, and more. (Please see our catalog for complete size and configuration details).

- Exceptional Corrosion Resistance (Specific Materials): Stainless steel options provide excellent corrosion resistance, making them suitable for use in harsh environments and with corrosive fluids.

- Easy Installation: While professional welding is required, the socket weld design simplifies the installation process compared to other types of fittings. This can lead to reduced installation time and cost.

- Full Traceability: Each fitting is traceable to its heat number and manufacturing batch, ensuring quality control and facilitating compliance with industry regulations.

Applications:

Our forged socket weld fittings are widely used in various industries including:

- Chemical Processing: Handling corrosive chemicals and fluids.

- Oil & Gas: High-pressure pipelines and processing equipment.

- Power Generation: Steam systems and other high-temperature applications.

- Pharmaceutical Manufacturing: Maintaining sterility and preventing contamination.

- HVAC/R Systems: Connecting refrigeration lines and other components.

Specifications: (To be provided upon request – include pressure ratings, temperature ratings, material specifications, dimensions, and relevant standards compliance information).

Ordering Information: (To be provided – include part numbers, size options, material specifications, and contact information).

Contact us today to discuss your specific requirements and receive a customized quote. We are committed to providing superior quality fittings and exceptional customer service.