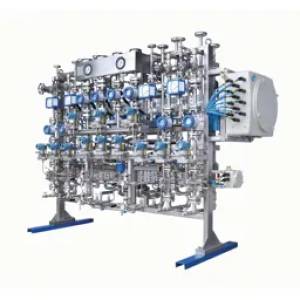

Revolutionize your sealing applications with our comprehensive range of Seal Support Systems. Designed to maximize the performance and longevity of your seals, our systems provide superior protection against premature wear, leakage, and costly downtime. Whether you're dealing with high-pressure, high-temperature, or chemically aggressive environments, we have the solution to meet your specific needs.

Why Choose Seal Support Systems?

Our Range of Products Includes:

Applications:

Our Seal Support Systems find application across a vast range of industries, including:

Materials:

We utilize a wide array of high-performance materials selected for their resistance to specific operating conditions. These include:

Contact Us:

To learn more about our Seal Support Systems and how we can help optimize your sealing applications, contact our team today. We offer comprehensive technical support and are committed to providing superior customer service. Request a quote or consultation to discuss your specific needs.