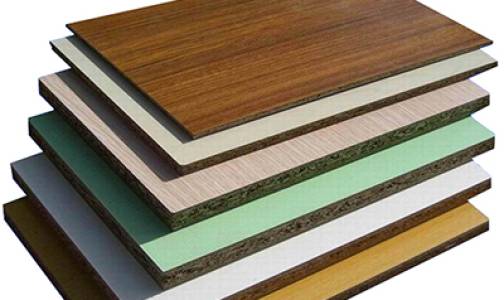

Laminated particleboard (LBP) offers a perfect balance of affordability, durability, and aesthetic appeal, making it an ideal choice for a wide range of applications. This engineered wood product combines the strength and stability of particleboard with a decorative and protective laminate surface. Whether you're a DIY enthusiast, a professional contractor, or a furniture manufacturer, LBP provides a cost-effective alternative to solid wood while maintaining a high-quality finish.

Key Features & Benefits:

Specifications (Typical, may vary depending on manufacturer and grade):

Considerations:

Choose Laminated Particleboard for a high-quality, cost-effective, and versatile solution for your next project!