Description

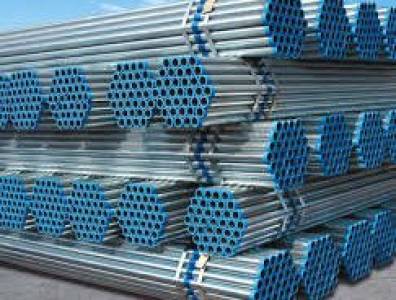

PRE-GALVANIZED (G.P.) & GALVANIZED IRON (G.I.) PIPES: A Comprehensive Guide

Introduction:

We offer a comprehensive range of high-quality pre-galvanized (G.P.) and galvanized iron (G.I.) pipes, ideal for a wide variety of applications demanding durability, corrosion resistance, and longevity. Understanding the subtle differences between G.P. and G.I. pipes is crucial for selecting the right product for your project.

Pre-Galvanized (G.P.) Pipes:

- Description: G.P. pipes undergo a pre-galvanization process where the steel is coated with zinc before the pipe is formed. This ensures complete and even zinc coating, providing superior corrosion protection compared to G.I. pipes. The pre-galvanization also enhances the pipe's strength and reduces the risk of surface imperfections.

- Advantages:

- Superior Corrosion Resistance: The complete and even zinc coating provides exceptional protection against rust and degradation, extending the lifespan of the pipe significantly.

- Enhanced Strength: The pre-galvanization process contributes to increased tensile strength and durability.

- Smoother Interior Finish: Leads to better flow characteristics for fluids, minimizing friction and pressure loss.

- Longer Lifespan: Significantly outlasts G.I. pipes in most environments.

- Applications: Ideal for various applications including:

- Water Supply Systems: Residential, commercial, and industrial plumbing.

- Irrigation Systems: For efficient and reliable water distribution.

- Gas Lines: In applications where corrosion resistance is paramount.

- Structural Applications: Where strength and durability are critical.

Galvanized Iron (G.I.) Pipes:

- Description: G.I. pipes are made from mild steel and are galvanized after the pipe is formed. This process involves dipping the pipe in a molten zinc bath to create a protective zinc coating.

- Advantages:

- Cost-Effective: Generally less expensive than G.P. pipes.

- Good Corrosion Resistance: Provides adequate protection against rust in many applications.

- Disadvantages:

- Uneven Coating: The post-galvanization process may result in a less uniform and complete zinc coating compared to G.P. pipes, potentially leading to reduced corrosion resistance in certain areas.

- Shorter Lifespan: Generally has a shorter lifespan compared to G.P. pipes.

- Applications: While suitable for various applications, G.I. pipes are generally preferred for less demanding projects where cost is a primary factor.

Specifications:

Both G.P. and G.I. pipes are available in a wide range of sizes, schedules (wall thickness), and lengths to meet diverse project requirements. Specific dimensions and specifications are available upon request. We adhere to stringent quality control measures to ensure that all our pipes meet or exceed industry standards.

Choosing the Right Pipe:

The selection between G.P. and G.I. pipes depends primarily on the specific application and budget considerations. For applications requiring superior corrosion resistance, longer lifespan, and enhanced strength, G.P. pipes are the preferred choice. For less demanding projects where cost is a significant factor, G.I. pipes may be a suitable option.

Contact Us:

Contact our sales team today to discuss your requirements and receive a customized quote for your G.P. and G.I. pipe needs. We are committed to providing high-quality products and exceptional customer service.