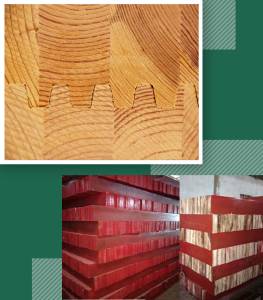

Laminated Veneer Lumber (LVL) is an engineered wood product offering exceptional strength, stability, and consistency, surpassing that of solid lumber. Manufactured from thin layers (veneers) of wood, typically softwood, bonded together with durable adhesive under high pressure, LVL provides a superior alternative for a wide range of structural applications.

Key Features & Benefits:

Specifications (Typical, may vary based on manufacturer and grade):

Choosing the Right LVL:

When selecting LVL, it's crucial to consider the following factors:

Contact Us:

For more information on selecting the right LVL for your project or to obtain detailed specifications and pricing, please contact us today. We're happy to assist you in choosing the best LVL solution for your needs.