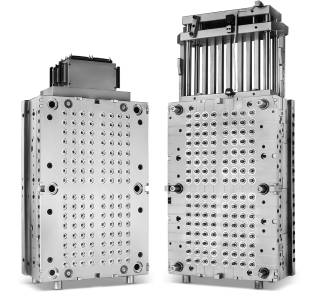

Elevate your manufacturing process with our meticulously crafted injection molds. Designed and manufactured to exacting standards, our molds deliver consistent, high-quality parts for even the most demanding applications. Whether you're producing millions of units or need a small batch run, we offer customized solutions tailored to your specific needs.

Unmatched Quality & Precision:

Benefits of Choosing Our Injection Molds:

Our Services Include:

Applications:

Our injection molds are suitable for a wide range of applications, including:

Contact us today to discuss your project and let us help you achieve your manufacturing goals with superior injection molds. We offer competitive pricing and exceptional customer service. Request a quote and let's begin building your ideal production solution.