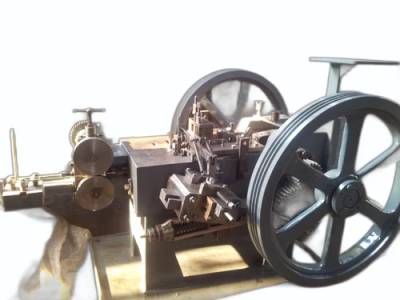

This state-of-the-art header machine is engineered for superior efficiency and precision in a variety of industrial applications. Whether you're working with automotive parts, aerospace components, electronics manufacturing, or other high-precision industries, our header machine delivers unmatched performance and reliability.

Key Features & Benefits:

Technical Specifications: (Replace placeholders with actual values)

Optional Add-ons:

Warranty: [Insert Warranty Details]

Contact us today to learn more about how our Header Machine can improve your manufacturing process and boost your bottom line! [Insert Contact Information]