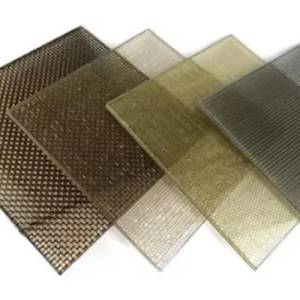

Laminated glass fabric offers a unique blend of strength, durability, and aesthetic appeal, making it an ideal choice for a wide range of applications. This innovative material combines the inherent strength of fiberglass fabric with the protective and enhancing qualities of a robust polymer laminate. The result is a product that surpasses the limitations of traditional fiberglass cloth, offering enhanced performance and longevity.

(Specific technical specifications will vary depending on the manufacturer and type of laminate used. Please refer to the manufacturer's datasheet for precise details.)

Selecting the appropriate laminated glass fabric depends on the specific application and required performance characteristics. Factors to consider include:

Contact us today to discuss your specific requirements and find the perfect laminated glass fabric for your project. We'll help you select the optimal product to meet your needs and ensure project success.