Our seamless pipes offer unparalleled performance and longevity across a wide range of applications. Manufactured using a sophisticated process that eliminates welds, these pipes provide superior strength, durability, and resistance to pressure and corrosion compared to their welded counterparts. This makes them ideal for demanding projects where reliability is paramount.

Key Features & Benefits:

Applications:

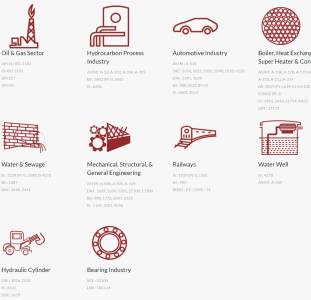

Seamless pipes are widely used in diverse industries, including:

Specifications:

Contact Us:

For detailed specifications, pricing, and ordering information, please contact our sales team. We're committed to providing you with the highest quality seamless pipes and exceptional customer service. We're happy to discuss your specific requirements and provide tailored solutions to meet your project needs.